Water Supply

Enhancement Technologies

|

| ___________________________________________________ |

Enhancement of water supply reservoir dissolved oxygen (DO) levels can be obtained using diffusers in the reservoir that utilize the driving force of the water to achieve high gas transfer efficiencies. The diffusers can be supplied with compressed air or oxygen from a liquid oxygen storage facility, pressure swing adsorption system or other gas supply system. A properly designed hypolimnetic oxygenation system for a water supply reservoir is sized to have the capacity to maintain the desired oxygen levels in the reservoir with enough reserve capacity to increase oxygen levels after a shutdown or mid-season startup. This capacity is typically evaluated by measuring the reduction in reservoir oxygen content during each season based on reservoir dissolved oxygen profiles and using some multiplication factors to account for additional known or unknown demands and provide a level of confidence that the system has sufficient capacity to operate as desired.

Oxygen can be placed at various elevations within the reservoir and over large areas through careful placement of the diffusers and design of the bubble plume characteristics. Over time the oxygen placed by the diffuser will spread laterally and provide direct coverage of high DO levels near the sediments, even several miles away from the diffuser.

|

|

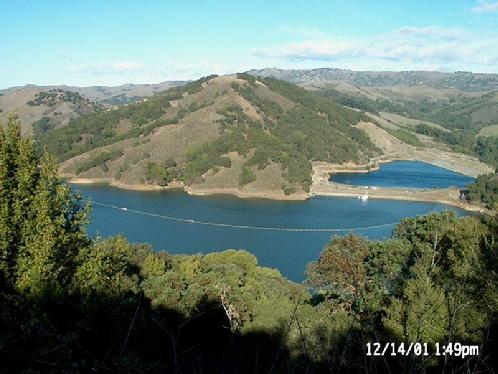

| Upper San Leadro Reservoir in California |

|

|

The line diffuser is a simple and economical design that spreads bubbles over a large area and is installed and retrieved for any required maintenance without divers. The system uses long lines of flexible porous hose to avoid clogging and other maintenance problems experienced by previous systems that used ceramic diffusers. The line diffuser has proven to be an efficient and economical aeration diffuser design that transfers oxygen efficiently, and minimizes mixing within the reservoir and avoids sediment re-suspension.

|

| ___________________________________________________ |

| ___________________________________________________ |

A side stream super-saturation system removes a portion of the water flow from the process, adds oxygen then distributes the oxygenated water back into the total water flow. The system uses high-pressure water so that oxygen can be dissolved to levels that are far greater than atmospheric saturation limits. A long length of pipe is required to provide contact time and mixing to dissolve the oxygen gas bubbles. The super-saturated water is then distributed using a diffuser and nozzles for liquid mixing. As applied to water supply, the water to be oxygenated can be removed from a specific elevation in the reservoir, oxygenated, and then returned to the same density layer. The size of the system depends on the pressure available and oxygenation required.

|

|